Your Flannelette Cure: Fire Tests with Textiles (1910)

Ballerinas on fire fascinated Victorians. It was an erotic, potent image, the subject of numerous prints: dewy, ethereal virgins licked by flames. But it was also a real thing, in that actual ballerinas caught fire on stage and died of horrific burns. In one such fire, for instance, in Philadelphia in 1861, a dancer’s tutu blazed, others rushed to help, and eight ballerinas burned to death, some in view of the audience. The charred remains of French ballerina Emma Livry’s costume are held in the collection of the Musée-bibliothèque de l'Opéra in Paris; the famous dancer lifted her tutu so that the tulle wouldn’t be smushed when she sat down to rest, and the tiny whoosh of air swelled a fatal gas lamp.

These deaths by fire grabbed headlines, but most others did not; it was shockingly commonplace for a woman to die because her clothing ignited. The problem was threefold. First, light was provided by flame. Second, fashions were so voluminous they couldn’t be closely controlled. And third, fabric. Some fabrics — lace, netting, gauze, tulle, muslin — were far more flammable than others. They ignited almost instantly, and burned fast and hot. Others, such as wool, were naturally fire-retardant. Women’s clothes were more often made of the former than the latter.

The number of fatalities increased in the last decade of the nineteenth century when a new fabric entered the market, flannelette. Flannelette was a poor woman’s flannel — a cotton calico that had been treated on one side with bladed rollers and brushes that abraded the surface, raising a kind of fiber fluff. Like its namesake, flannelette promised warmth, which was desirable on its own, but also thought to prevent illness. It was used extensively for undergarments, pajamas, and children’s clothes.

The fabric turned out to be extraordinarily flammable, “almost as dangerous, if touched with fire, as gunpowder”, wrote a contemporary observer. Like dry brush in a forest, the buttery nap accelerated fire, such that a spark at a nightgown’s hem could spread to the collar in fifteen seconds. As the deaths increased, Britain’s coroners began raising alarms. Some coroners went so far as to suggest that flannelette should be banned, which is when one of the largest manufacturers, Manchester’s Messrs Whipp Bros & Tod, finally took action.

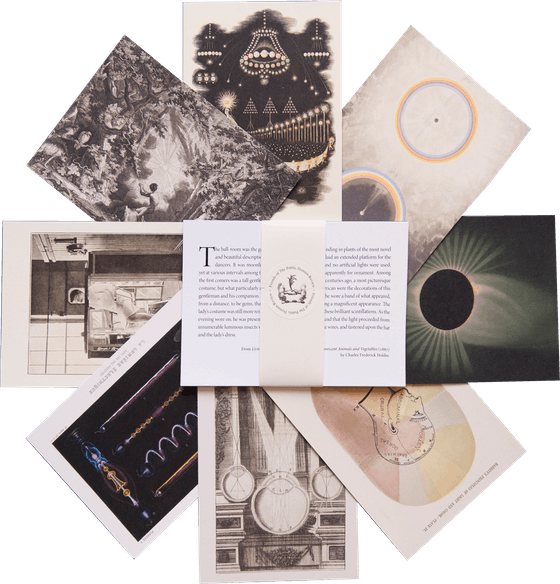

A 1910 demonstration of the flammability of “non-flam” flannelette vs ordinary flannelette — Source.

The company hired chemists and fire scientists to determine if flannelette could possibly be made less flammable. It was a difficult ask. Existing fire retardants were unsuitable for clothing — they turned fabric dusty, flaky, or clammy. Messrs Whipp Bros & Tod needed something that wouldn’t affect the tactility, color, or smell of the flannelette, and was organic enough for skin contact. Most challenging of all, the retardant had to stay put through repeated washings. It wasn’t practical for the average flannelette consumer to dip the garment over and over, in a separate tub, at extra expense, with time for drying before and after.

The images above document just a tiny fraction of the ten thousand burning tests ultimately performed. The process was rigorous. Messrs Whipp Bros & Tod’s experiments controlled for weather, clothing size, number of washes, and the specific type of washing, whether by machine or hand, with elaborate specs for each. (The handwashing process, for instance, entailed fabric being: “rinsed in cold water, then washed and boiled in Field’s pure oil soap and Brunner Mond’s alkali, then rinsed once with warm water, rinsed twice with cold water, centrifuged, dried in moderate heat, ironed.”) Ignition by candle was compared to ignition by gas lamp.

The basic experiment, run over and over again, was to set fabric on fire, watch it burn for sixty seconds, and then document the percentage of total destruction. Messrs Whipp Bros & Tod ultimately concocted a product that did very well in these tests, well enough to earn approval from the British Fire Prevention Committee. A size large nightgown made of ordinary flannelette and washed and ironed 10 times was more than half in cinders after 60 seconds, whereas a size large nightgown made of the new treated flannelette, also washed and ironed 10 times, remained entirely intact even at 120 seconds. (The photos show a tiny swatch burned out of the hemline, and no other damage.) “Non-Flam Flannelette” hit the market in 1910, with hopes that it would replace flannelette entirely. Even more lifesaving was the switch from gas to electric light. There is always another way to skin a cat.

Enjoyed this piece? We need your help to keep publishing.

The PDR is a non-profit project kept alive by reader donations – no ads, no paywalls, just the generosity of our community. It’s a really exciting model, but we need your help to keep it thriving. Visit our support page to become a Friend and receive our themed postcard packs. Or give a one-off donation. Already a supporter? A huge thank you for making all this possible.

Oct 19, 2023